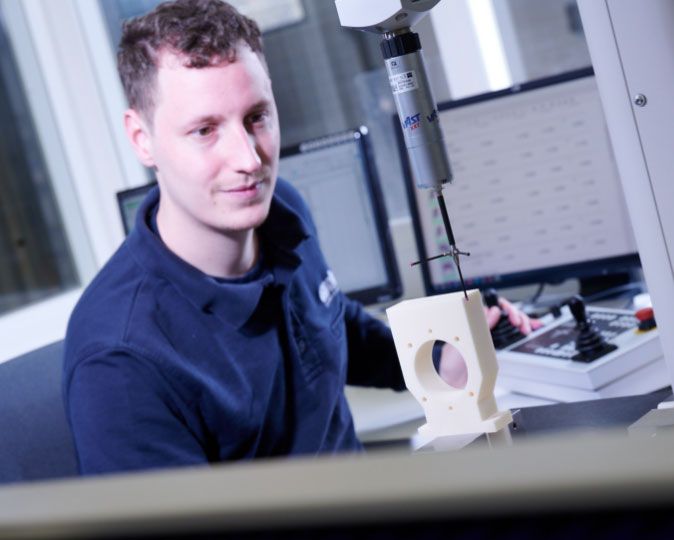

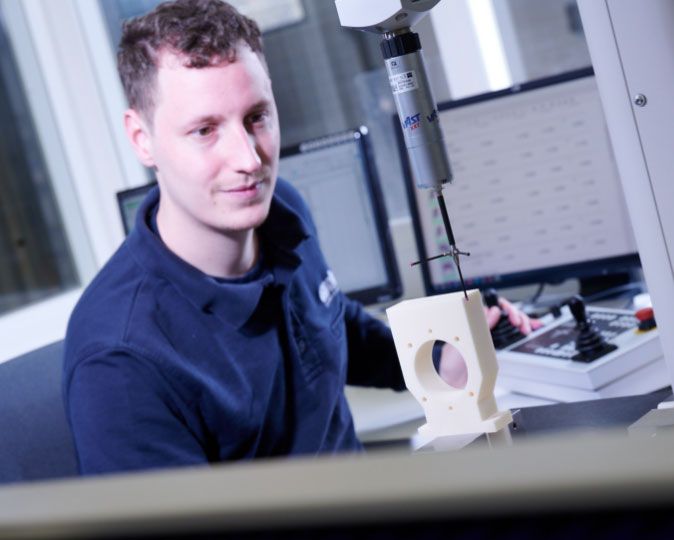

Fully integrated quality management – certified to DIN ISO 9001

Our test equipment management system ensures that the calibrated test equipment best suited for the purpose is used every time.

ceratec QUALITY

It’s better to insist on the best!

DIN ISO 9001 certification is simply the icing on the cake of our fully integrated quality management system. For us, quality management is not something that goes on behind closed doors – it’s a part of our everyday production routine.

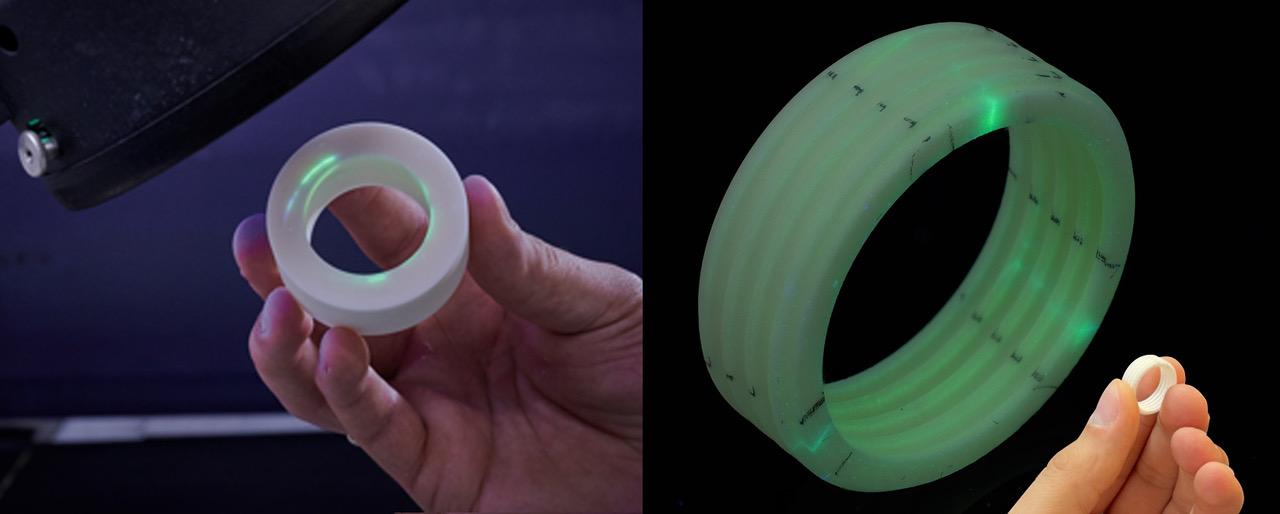

We firmly believe that quality must be not simply well-planned but also permanently assured. That’s why we map out all our production processes in as much detail as possible. Every production step is traceable throughout, all the way to the raw material we set out with. Parallel to this, we prepare an individual inspection plan for each component in consultation with the customer. Our in-process and final quality controls are carried out according to a combination of customer requirements and our own criteria.

Test reports

Quality management

3D coordinate measuring machines

In-process inspection

All components undergo a one-hundred-percent crack examination.

Certified to

DIN ISO 9001

Convincing arguments – click here to take a look at our certification!

Jobs

No matter whether you’re a seasoned professional or a career entrant – if good future prospects are important to you, then we could be exactly what you’re looking for. We supply a variety of products to growth markets – providing valuable peace of mind. Last but not least, a respectful working environment at a dynamic family business awaits you.